Arrangement of Axes and Drive System

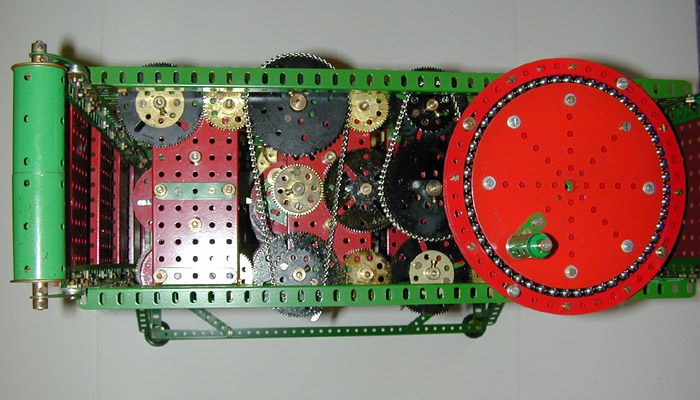

In addition to these there are a number of additional axes in the model that do not necessarily have corresponding axes in the original. The picture below shows top view of the machine with the main drive crank removed. The front of the machine is at the bottom in this picture.

If you click on the picture above, you should get a larger image, annotated to identify each of the axes. The numbers on the picture correspond to the table below. For each axis there are four cages (to use Babbage's notation). Cage 1 is lowest with the units digit, cage 2 is next above with the 10's digit, cage 3 above that with the 100's digit, and finally cage 4 is at the top with the 1000's digit. Depending on both the axis and the cage, a different set of components may be required.

| Number |

Axis |

Comments |

|---|---|---|

| 1 |

Result |

This

is the main result axis. The rod is undriven and all elements are free

to rotate on it. Each cage contains a digit wheel. |

| 2 |

Intermediate |

Split

into segments vertically. Each segment carries two fixed 57t gear

wheels to connect the digit wheel on

the result axis to the corresponding readout cage on the first

difference axis. Each segment also carries a fixed detent wheel. All 4

cages similar. |

| 3 |

First

Difference |

The

first difference axis. Driven at the rate of one revolution per turn of

the crank. Readout cages fixed

on the rod. Each cage

contains a digit wheel and a readout assembly. The 1½" sprocket in the drive

mechanism bolted to the 2½" gear provides the drive to the carry

axes. |

| 4 |

Intermediate |

Split

into segments vertically. Each segment in cages 1, 2, and 3

carries two fixed 57t gear wheels to connect the digit wheel on the first

difference axis to the corresponding readout cage on the second

difference axis. Each

segment

also carries a fixed detent wheel. Since there is no digit in cage 4

of the second difference axis, the upper segment carries only a single

57t

gear and a detent wheel. The 57t gear in the drive

mechanism

is free to turn on the upper segment and acts as an idler between the

two

driving 2½" gears. |

| 5 |

Second

Difference |

The second difference axis. Driven at the rate of one revolution per turn of the crank. Each of cages 1, 2, and 3 contains a digit wheel and a readout assembly. Cage 4 is empty. |

| 6 |

Intermediate |

Split

into segments vertically. Each segment in cages 1 and 2

carries two fixed 57t gear wheels to connect the digit wheel on the second difference axis to

the corresponding readout cage on the third difference axis. In cage 3

the segment has just a single 57t gear and a detent wheel. The fourth

cage is empty.

The 57t gear in the drive mechanism is fixed on the upper segment of

the rod. It acts as an idler between the two driving 2½" gears. |

| 7 |

Third

Difference |

The

third difference axis.

Driven at the rate of one revolution per turn of the crank. Each of cages 1 and 2 contains a

digit wheel and a readout assembly. Cages 3 and 4 are

empty. The 2" sprocket

in

the drive mechanism bolted to the 2½" gear receives the drive

from

the main crank. |

| unmarked |

Intermediate |

Split

into segments vertically. In cages 1 and 2 each segment

carries a single 57t gear and a detent wheel. Cages 3 and 4 are

completely empty, so this axis is not visible in the picture above, but

it occupies a similar position relative to the third difference axis as

axis #6 does to the second difference axis. |

| 8 |

Detent |

Undriven,

this rod carries the bell

cranks providing the detents for the digit wheels on the result axis. All four cages similar. |

| 9 |

Detent |

Undriven,

this rod carries the bell

cranks providing the detents for the digit wheels on the first

difference

axis. All four cages similar. |

| 10 |

Detent |

Undriven,

this rod carries the bell

cranks providing the detents for the digit wheels on the second

difference

axis. Only cages 1, 2, and 3 have this

assembly. Cage 4 is empty. |

| 11 |

Detent |

Undriven,

this rod carries the bell

cranks providing the detents for the digit wheels on the third

difference

axis. Only cages 1, and 2 have this assembly. Cages 3 and 4 are empty. |

| 12 |

Carry

Intermediate |

Undriven,

this rod holds the face plate and gear assemblies of the carry

mechanism in cages 2, 3, and 4. All elements are free to turn on the

rod. Cage 1 is empty since there is no carry into the units digit. |

| 13 |

Carry

Trip |

Split

into segments vertically. Each segment carries two pawls and the double

arm crank assembly. Provides

the carry trip linkage from one digit to the next higher digit. These

assemblies span two cages since this is the path to communicate the

carry

information from one digit to the next higher. Thus there are three

segments,

between cages 1 and 2, cages 2 and 3, and cages 3 and 4. The lower pawl

is in the lower of the two connected cages. The upper pawl and crank

assembly

are in the upper of the two connected cages. |

| 14 |

Bolting |

First

difference bolting axis. Driven at the rate of one revolution per four

turns of the crank. The bolting

assemblies are fixed on this rod in all four cages. The face plate and

gear assemblies of the carry mechanism in cages 2, 3, and 4 are also

mounted

on this rod, but free to turn. Cage 1 has no face plate and gear

assemblies

since there is no carry into the units digit. |

| 15 |

Carry

Trip |

Split

into segments vertically. Each segment carries two pawls and the double

arm crank assembly. Provides

the carry trip linkage from one digit to the next higher digit. These assemblies span two cages

since this is the path to communicate the carry information from one

digit to

the next higher. Thus there are three segments, between cages 1

and

2, cages 2 and 3, and cages 3 and 4. The lower pawl is in the lower of

the

two connected cages. The upper pawl and crank assembly are in the upper

of

the two connected cages.

The 2½" gear in the drive mechanism is free to turn on the rod.

It

acts as an idler between the two driving 57t gears. |

| 16 |

Bolting |

Second

difference

bolting axis. Driven at the rate of one revolution per four turns of

the crank. The bolting assemblies are fixed on this rod in cages 1, 2,

and 3. Cage 4 is empty. The

face plate and gear assemblies of the carry mechanism in cages 2 and 3

are also mounted on this rod, but free to turn. Cages 1 and 4 have no

face

plate and gear assemblies since there is no carry into the units digit

and

no digit wheel in cage 4. The 3" sprocket in the drive mechanism is

bolted to a 57t gear below and receives the drive from the carry axes.

|

| 17 |

Carry

Trip |

Split

into segments vertically. Each segment carries two pawls and the double

arm crank assembly. Provides the carry trip linkage from one digit to

the next higher digit. These

assemblies span two cages since this is the path to communicate the

carry information from one digit to

the next higher. There are two segments, between cages 1 and 2,

and

cages 2 and 3. The lower pawl is in the lower of the two connected

cages.

The upper pawl and crank assembly are in the upper of the two connected

cages. The 2½"

gear

in the drive mechanism is fixed on the upper segment of the rod as there is no carry

trip on the top two segments of the second difference axis. It acts as an idler between the

two driving 57t gears. |

| 18 |

Bolting |

Third

difference

bolting axis. Driven at the rate of one revolution per four turns of

the crank. The bolting assemblies are fixed on this rod in cages 1 and

2. Cages 3 and 4 are empty. There

are no carry mechanism components on this rod, the third difference

being

a constant. |

| 19 |

Carry

Stop |

Nothing

is mounted on this rod. It provides a stop for the 1½" narrow

strip on the face plate of the carry mechanism. |

| 20 |

Carry

Stop |

Nothing

is mounted on this rod. It provides a stop for the 1½" narrow

strip on the face plate of the carry mechanism. |

| 21 |

Carry

Stop |

Nothing

is mounted on this rod. It provides a stop for the 1½" narrow

strip on the face plate of the carry mechanism. |

| 22 |

Carry |

Result

carry axis. Driven at the rate of one revolution per two turns of the

crank. Carry reset arms are fixed to the rod in cages 2, 3, and 4. Cage

1 is empty since there is no carry

into the units digit. This

rod also provides the anchor for the tension springs on the carry

mechanism faceplates. |

| 23 |

Intermediate |

This

rod carries a 57t gear which acts as an idler between the two driving

2½" gears. The rod extends

the full height of the machine and provides the anchor for the

carry

trip tension springs. |

| 24 |

Carry |

First difference carry axis. Driven at the rate of one revolution per two turns of the crank. Carry reset arms are fixed to the rod in cages 2, 3, and 4. Cage 1 is empty since there is no carry into the units digit. The 3" sprocket in the drive mechanism is bolted to a 2½" gear below and brings the drive from the first difference axis. This rod also provides the anchor for the tension springs on the carry mechanism faceplates. |

| 25 |

Intermediate |

This

rod carries a 57t gear which acts as an idler between the two driving

2½" gears. The rod extends the full height of the machine and

provides the anchor for the carry

trip tension springs. |

| 26 |

Carry |

Second difference carry axis. Driven at the rate of one revolution per two turns of the crank. Carry reset arms are fixed to the rod in cages 2, and 3. Cages 1 and 4 are empty since there is no carry into the units digit and no digit wheel in cage 4. The 1½" sprocket in the drive mechanism is bolted to the 2½" gear below and provides the drive to the bolting axes. This rod also provides the anchor for the tension springs on the carry mechanism faceplates. |

| 27 |

Intermediate |

Undriven,

this rod extends the

full height of the machine and provides the anchor for the carry

trip tension springs. |

In order to handle the fairly high torque required to drive the entire machine a few points should be noted. Each driven rod is driven by a gear which is bolted to a second bossed part. Washers are used as spacers. Two set screws are used, one in each boss. This provides a very secure drive to a single axis.

Next, note that all the axes in a given rank are geared together through the idlers, thus there is no point where the bosses and set screws have to carry the torque of more than a single axis.

Finally, the drive between the three ranks is through the chains. The sprockets form one of the double elements, being bolted to a gear below so again the transmission is accomplished without the torque going through the bosses and set screws.

The picture below shows the top of the machine with the main crank in position. It is bolted to the frame members by four 1 1/8" bolts with collars and washers as spacers as required to align the 2" driving sprocket with the sprocket on the third difference axis.

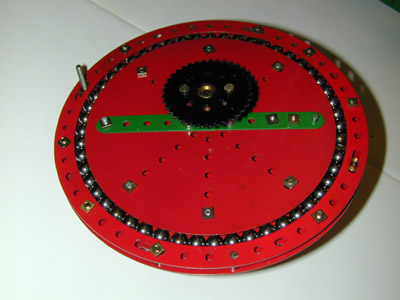

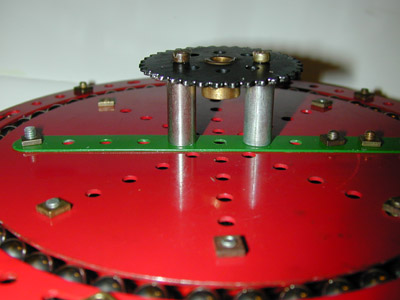

Construction of the crank itself is straight forward. It consists of two 6" circular plates spaced apart with collars and Electrikit thin washers in eight places, and a pair of 7½" circular strips similarly spaced in 12 places, four of these being the mounting bolts to the frame. The space between the circular plates and the circular strips is filled with 3/8" balls, a task which will prove very frustrating to accomplish! On the top side a handle is formed from a sleeve piece mounted on a pair of chimney adapters, a ¾" washer preventing it from being able to slip down. The rod carrying the handle is fixed in a crank on the top side and protrudes through into a 5½" strip bolted on the underside to provide a round hole.

|

|

| The

view to the right shows a somewhat clearer view of the mounting of the

main drive sprocket. Electrikit 1"

round cores are used as spacers. When the crank is first assembled, it should be fairly tight to turn. Lubricate the balls well. After some use it should bed in and operate smoothly. |

|

Framework

> Arrangement of axes and drive system

Decimal digit storage

Digit readout and addition

Carry detection and propagation

Setup and adjustment

Operation

Parts list

Last modified: 23 July 2004 If you experience any problems with this site, please contact the webmaster |

©

2003, 2004 Tim Robinson |